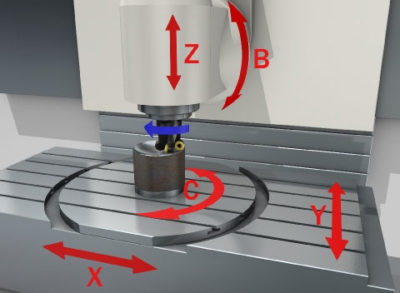

We have standardized on Mazak® HMC and VMC CNC machining centers; many with tombstone setup’s to maximize production throughput. SMW has up to 5-axis capability to machine parts of complex geometry. Our machines have been selected on common platforms to ensure that our tooling and setup’s are identical and thereby reduce the risk of work stoppages due to machine down-time. Our programmers utilize the latest CAD/CAM software to ensure a faithful replication of the design supplied on our customers engineering drawings. All of our machines are regularly inspected on a schedule; documentation of this maintenance resides in a special folder at each machine.

We have standardized on Mazak® HMC and VMC CNC machining centers; many with tombstone setup’s to maximize production throughput. SMW has up to 5-axis capability to machine parts of complex geometry. Our machines have been selected on common platforms to ensure that our tooling and setup’s are identical and thereby reduce the risk of work stoppages due to machine down-time. Our programmers utilize the latest CAD/CAM software to ensure a faithful replication of the design supplied on our customers engineering drawings. All of our machines are regularly inspected on a schedule; documentation of this maintenance resides in a special folder at each machine.

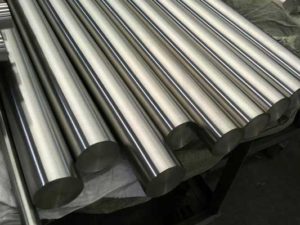

Again, our shop has standardized on Mazak® CNC lathes for our production turning work. We utilize a best practices Machine redundancy philosophy to ensure we never let your production schedule slip. We’re able to provide turning, facing, boring, chamfering, grooving, forming, threading, and other operations. With the ability to turn up to a 20-inch diameter part, SMW is able to handle a wide array of turned components.

Again, our shop has standardized on Mazak® CNC lathes for our production turning work. We utilize a best practices Machine redundancy philosophy to ensure we never let your production schedule slip. We’re able to provide turning, facing, boring, chamfering, grooving, forming, threading, and other operations. With the ability to turn up to a 20-inch diameter part, SMW is able to handle a wide array of turned components.

Southern Machine Works has built long standing relationships with qualified local sub-contractors to provide ancillary machining technologies. We can provide (but not limited to):

Southern Machine Works has built long standing relationships with qualified local sub-contractors to provide ancillary machining technologies. We can provide (but not limited to):

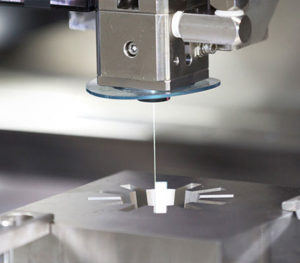

√ Wire EDM & Sinker

√ Broaching

√ Centerless & Planar Grinding

√ Gun Drilling

√ Reaming & Honing

√ Forging, Casting, & Extrusions

√ Water Jet Cutting

Our welders are AWS certified and have extensive experience with these welding types:

Our welders are AWS certified and have extensive experience with these welding types:

√ Shielded metal arc welding (SMAW)

√ Gas metal arc welding (GMAW) aka MIG welding

√ Gas tungsten arc welding (GTAW) aka TIG welding, Heliarc®

Additionally, we can provide brazing and silver brazing processes.

Generally speaking, we can provide the above services on Carbon Steels, Stainless Steel, Aluminum, and brass (brazing only).

SMW has a diverse capability to provide assemblies and fabricated structures in a variety of sizes and complexity. Whether your need is for a “one off” or production levels, SMW can provide accurate and quality assemblies and fabrications.

SMW has a diverse capability to provide assemblies and fabricated structures in a variety of sizes and complexity. Whether your need is for a “one off” or production levels, SMW can provide accurate and quality assemblies and fabrications.

To mitigate supply chain risk, savvy OEM’s choose to ensure a safety stock of inventory is always on hand to accommodate upswings in product demand and smooth running production assembly lines. To this end, Southern Machine Works provides value-added inventory control solutions to work in conjunction with our customers JIT and Kanban supply chain needs. With these controls in place, SMW can respond immediately to deliver OEM component shipments and then automatically backfill those components on our shelves for future demand needs.

To mitigate supply chain risk, savvy OEM’s choose to ensure a safety stock of inventory is always on hand to accommodate upswings in product demand and smooth running production assembly lines. To this end, Southern Machine Works provides value-added inventory control solutions to work in conjunction with our customers JIT and Kanban supply chain needs. With these controls in place, SMW can respond immediately to deliver OEM component shipments and then automatically backfill those components on our shelves for future demand needs.

Southern Machine Works welcomes prototype and short run production jobs. Our OEM customers have seen the benefits of including SMW during the prototyping process to ensure timely outcomes and effective solutions to design challenges. Our OEM customers benefit from Design-for-Manufacturing (DFM) expertise which often translates into overall lower component costs, savings on tooling and fixture costs, and faster job completion. SMW welcomes the opportunity to work in concert with your design team to ensure your development projects have successful and expeditious results. From rapid prototyping models, to first-article samples, and pre-production runs….SMW can play a valuable role in your product development process.

Southern Machine Works welcomes prototype and short run production jobs. Our OEM customers have seen the benefits of including SMW during the prototyping process to ensure timely outcomes and effective solutions to design challenges. Our OEM customers benefit from Design-for-Manufacturing (DFM) expertise which often translates into overall lower component costs, savings on tooling and fixture costs, and faster job completion. SMW welcomes the opportunity to work in concert with your design team to ensure your development projects have successful and expeditious results. From rapid prototyping models, to first-article samples, and pre-production runs….SMW can play a valuable role in your product development process.

From our half century of machining experience, SMW has proven its ability to be a reliable and forward-thinking manufacturing partner. Our customers glean the benefit of our years of experience in the machining business. SMW can provide your design team expert level Design for Manufacturing (DFM) guidance. The potential benefits are:

From our half century of machining experience, SMW has proven its ability to be a reliable and forward-thinking manufacturing partner. Our customers glean the benefit of our years of experience in the machining business. SMW can provide your design team expert level Design for Manufacturing (DFM) guidance. The potential benefits are:

√ lower component costs

√ savings on tooling and fixture costs

√ raw material cost savings

√ faster job completion

Our team is standing by to assist your companies DFM consulting needs.